Heavy & Thin Gauge Vacuum Thermoforming Parts

dunnage

Full Service Custom Plastic Thermoformed

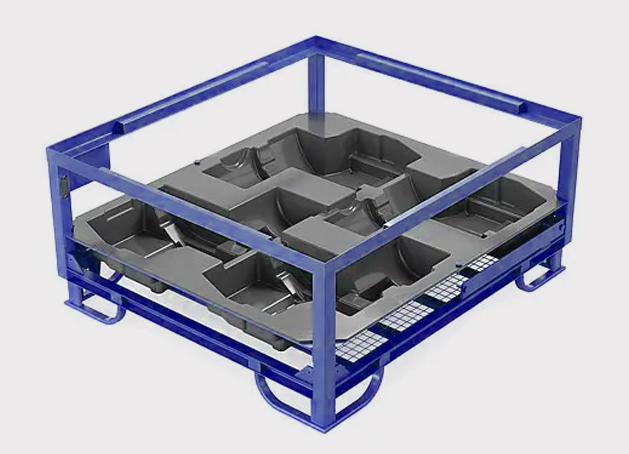

INPS manufactures custom dunnage components for original equipment manufacturers.

The design of these components optimize space while protecting customer's parts during transit.

Customers collaboration with our engineering and design groups help streamline the development of components from prototypes through to production requirements.

vacuum forming

Vacuum formed trays are an ideal way of protecting assemblies or components during transit. These trays can be designed for part specific usage with compliance to fit the designated container dimensions.

- Custom packaging components

- Industrial racking components

- Large scale formed dunnage for parts

vacuum formed storage of parts

Vacuum forming with part specific design allows for individual storage of parts and complete protection.

- Customer’s custom design accommodating parts

- Fit for Industrial racking of components

- Forming to fit container specifications

vacuum formed storage

Trays can be designed with minimal protection of parts or with a substantial barrier to protect the given part or assembly. Through collaboration with our Engineering team, we feel confident we have a solution for your application.

- Multi Layer Cavity

- Custom Cavity

- Heavy Duty Materials

- Clam Shell Design

- Re-usable Components

components separators

Trays can be the solution when stacking production parts. This illustration is an example of production parts being stacked for shipment with total separation of each part on each layer.

- Multi Layer

- Single Cavity

- Re-usable Components

vacuum formed dunnage

Solutions can be designed around most standard industrial shipping containers. Vacuum Forming has perpetual capabilities when it comes to the shape and sizes that can be achieved. INPS feels confident in providing a solution to most dunnage needs.

- Organized stacking panels

- Creative solutions for dunnage requirements

market sectors

AEROSPACE

AGRICULTURAL

CONSTRUCTION

DEFENSE

DUNNAGE

ELECTRONIC EQUIPMENT

FORESTRY

HEALTHCARE

MANUFACTURING

MINING

OIL & GAS

RAIL

TRANSIT

UTILITIES